S2CT will offer its customers a full portfolio of hardware components and products with turnkey and customized embedded software designed specifically for the end-to-end global supply chain.  The S2CT's Communications Hub, its functionality and subsystems, printed circuit board design, and power subsystem anchor the S2CT hardware product portfolio. The fully populated Communications Hub circuit board supports a microprocessor running an embedded Linux Operating System, a Data Logger capable of storing up to 6 months of data, GPS, GMDN (Global Mobile Data Network), Wi-Fi, Sub GHz, Satellite, I/O ports, Tamper Detection, Integrated Sensors and Power Subsystems. S2CT will offer its customers GMDN Global SIMs from its telematics partners, at very competitive pass-through data plan fees reaching less than $2 per month for 1 MByte of data, or allow them to provide their own SIMs and manage their own data plans. The microprocessor hosts a basic application layer to manage device security and authentication, subsystem configuration tables, a Communications Manager, device maintenance data collection, Over-the-Air software upgrade, and event / alarm handling. The microprocessor also hosts a value-added application layer for location-aware and cognitive advanced power management and customer custom functions.

The S2CT's Communications Hub, its functionality and subsystems, printed circuit board design, and power subsystem anchor the S2CT hardware product portfolio. The fully populated Communications Hub circuit board supports a microprocessor running an embedded Linux Operating System, a Data Logger capable of storing up to 6 months of data, GPS, GMDN (Global Mobile Data Network), Wi-Fi, Sub GHz, Satellite, I/O ports, Tamper Detection, Integrated Sensors and Power Subsystems. S2CT will offer its customers GMDN Global SIMs from its telematics partners, at very competitive pass-through data plan fees reaching less than $2 per month for 1 MByte of data, or allow them to provide their own SIMs and manage their own data plans. The microprocessor hosts a basic application layer to manage device security and authentication, subsystem configuration tables, a Communications Manager, device maintenance data collection, Over-the-Air software upgrade, and event / alarm handling. The microprocessor also hosts a value-added application layer for location-aware and cognitive advanced power management and customer custom functions.

The Communications Hub's Printed Circuit Board (PCB), populated with the components that support the desired functionality, is illustrated here. S2CT's objective of designing a "Universal" plastic enclosure for all it hardware products required consideration of this PCB and the Power Subsystem, battery pack, necessary for a typical battery life of 3+ years. With this consideration in mind and after evaluation of a number of long life primary battery chemistries and sizes, the Communications Hub double-sided PCB dimensions are set to 52 mm by approximately 100 mm.

The Communications Hub's Printed Circuit Board (PCB), populated with the components that support the desired functionality, is illustrated here. S2CT's objective of designing a "Universal" plastic enclosure for all it hardware products required consideration of this PCB and the Power Subsystem, battery pack, necessary for a typical battery life of 3+ years. With this consideration in mind and after evaluation of a number of long life primary battery chemistries and sizes, the Communications Hub double-sided PCB dimensions are set to 52 mm by approximately 100 mm.  S2CT has developed a unique antenna cable management system that reduces four cables, GPS, GMDN, Wi-Fi, Sub GHz and potentially a fifth for Satellite to one. S2CT is working to complete the development of a Magnetic Inductance connection to replace even that single cable.

S2CT has developed a unique antenna cable management system that reduces four cables, GPS, GMDN, Wi-Fi, Sub GHz and potentially a fifth for Satellite to one. S2CT is working to complete the development of a Magnetic Inductance connection to replace even that single cable.

The patented, Open License, Universal Enclosure, illustrated here, is intended to house all S2CT customer products in all application scenarios. The enclosure is fabricated using high-impact plastic and is IP67 dust tight and water-resistant.  The Universal Enclosure is based on the concept of a Rectangular Enclosure of fixed dimensions inserted into an Exoskeleton Main Body enclosure with customizable slide-on Exoskeleton Side-caps having flexible dimension and shape. The Rectangular Enclosure is designed to accommodate a double-sided Printed Circuit Board (PCB) with its connectors and a Battery Pack with its connector. The Rectangular Enclosure can be deployed as a standalone enclosure when assembled with its fitted End-caps and Cable Compartment. Alternatively, the Rectangular Enclosure, with its front and rear End-caps installed but without its Cable Compartment, can be inserted into an Exoskeleton Main Body with custom left and right Side-caps, specifically shaped such the resultant assembled enclosure is form-fit to the installation target area's shape. Designed to precisely match the shape of a particular cargo container's corrugated well for example.

The Universal Enclosure is based on the concept of a Rectangular Enclosure of fixed dimensions inserted into an Exoskeleton Main Body enclosure with customizable slide-on Exoskeleton Side-caps having flexible dimension and shape. The Rectangular Enclosure is designed to accommodate a double-sided Printed Circuit Board (PCB) with its connectors and a Battery Pack with its connector. The Rectangular Enclosure can be deployed as a standalone enclosure when assembled with its fitted End-caps and Cable Compartment. Alternatively, the Rectangular Enclosure, with its front and rear End-caps installed but without its Cable Compartment, can be inserted into an Exoskeleton Main Body with custom left and right Side-caps, specifically shaped such the resultant assembled enclosure is form-fit to the installation target area's shape. Designed to precisely match the shape of a particular cargo container's corrugated well for example.

The diagram and the video below illustrate shapes possible with the Universal Enclosure.

The width and height of the Rectangular Enclosure are driven by the choice of battery type in the Electronics Module. The Antenna PCB width is restricted to the Electronics PCB width in order to use the same core enclosure components, End-caps, etc., for both the Electronics and Antenna Modules. The length of the Rectangular Enclosure and therefore the Exoskeleton Main Body and Side Caps is arbitrary, determined by the length required by the assembled components housed within each, PCB, Batteries, etc.

The Communications Hub PCB and its basic embedded software layer are designed to yield all S2CT hardware product variations by depopulating the components that are not required without impacting the operation of the remaining component and resultant PCB. A simple Asset Monitor can be built around the same PCB without the GPS, GMDN, Wi-Fi or Satellite components. The Power Subsystem is also designed for maximum utility and can easily be scaled down from the Communications Hub requirements to support any other S2CT product in the Universal Enclosure. The Universal Enclosure is designed with the same scaling in mind and the extrusion fabrication method allows the main bodies of the Rectangular Enclosure and Exoskeleton Side Caps to vary infinitely in length, figuratively speaking of course. The Exoskeleton Side Caps provide a method to produce a final enclosure shape perfectly suited for any mounting target, flat against a wall, trapezoidal for corrugated walls or even circular for mounting on a light pole in a shipping terminal. The embedded software platform was conceived and is designed with those same objectives in mind. Maximum utility coupled with design-for-manufacturability.

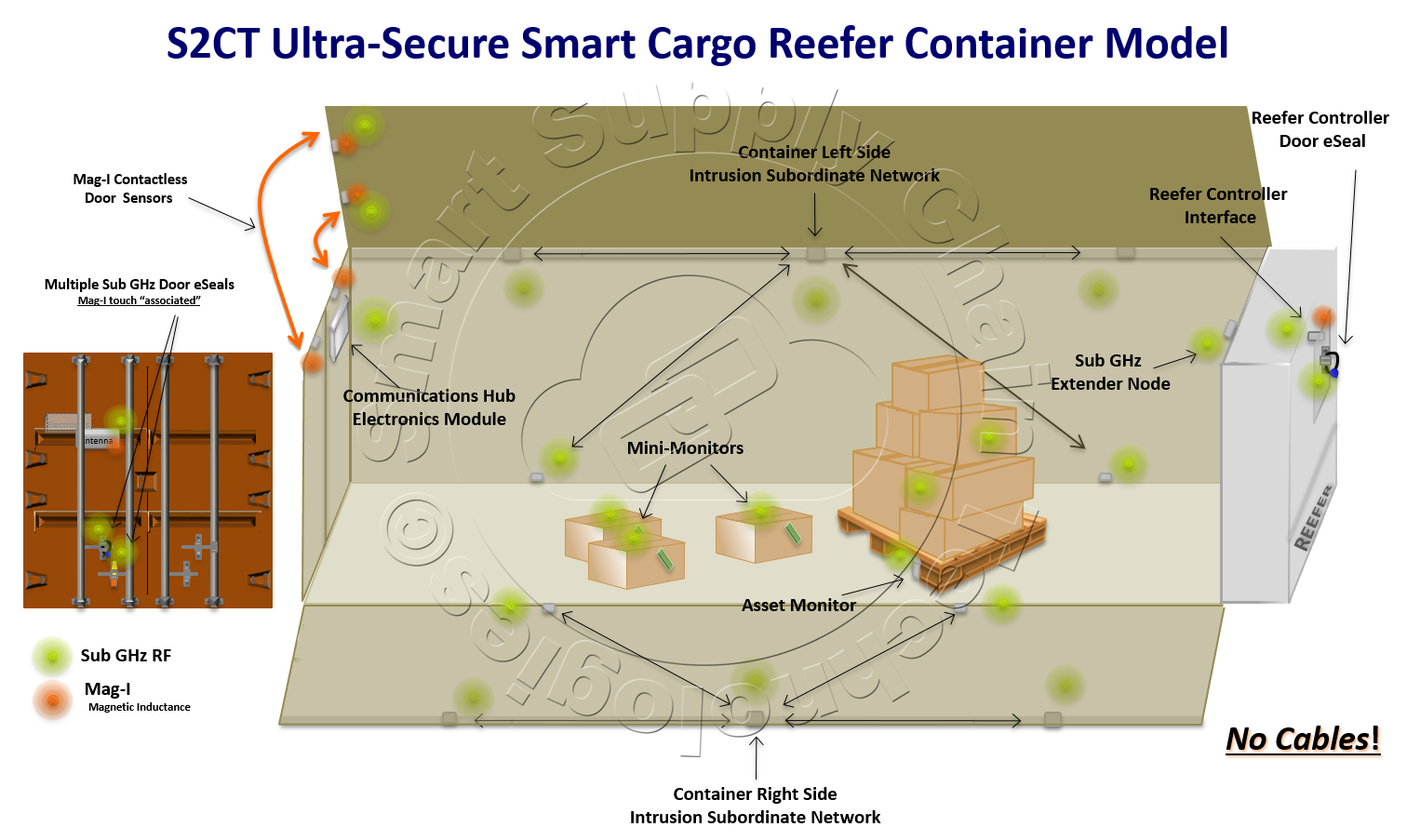

The figure to the right illustrates S2CT's initial target design, an Ultra-Secure Smart Reefer Container, derived from our insights into the needs of the One Belt, One Road Trade Lane, also known as The New Silk Road, and many other similar trade lane environments around the world.

The figure to the right illustrates S2CT's initial target design, an Ultra-Secure Smart Reefer Container, derived from our insights into the needs of the One Belt, One Road Trade Lane, also known as The New Silk Road, and many other similar trade lane environments around the world.

Note again, that all of the products illustrated in the Ultra-Secure Smart Reefer use the same core PCB, power subsystem, battery technology, the S2CT Universal Enclosure and core embedded software.

This container's security features two Intrusion Subordinate Networks, one on the left wall, positioned in such a manner to cover the left wall, left ceiling and left floor, and one on the right wall, positioned in such a manner to cover the right wall, right ceiling and right floor.  Each Sensor Node in the Intrusion Network collects data from its integrated sensors, analyzes it against its adaptive "event" profile and determines if the data constitutes a "subordinate-event" or not. If the Sensor Node determines that the data does not constitute a subordinate-event the data is integrated into Sensor Node's Adaptive Event Profile, enhancing the systems cognitive analytics, learning. Upon determining that the data constitutes a subordinate-event the Sensor Node immediately sends it to the Sensor Network Master Unit for further analysis and action. The Sensor Network Master Unit evaluates subordinate-event data it receives in the context of its network wide adaptive event profile and Network Master Analytics and decides to either store the data in its data logger or immediately send it to the Communications Hub for further evaluation and potential transmission to the asset owner.

Each Sensor Node in the Intrusion Network collects data from its integrated sensors, analyzes it against its adaptive "event" profile and determines if the data constitutes a "subordinate-event" or not. If the Sensor Node determines that the data does not constitute a subordinate-event the data is integrated into Sensor Node's Adaptive Event Profile, enhancing the systems cognitive analytics, learning. Upon determining that the data constitutes a subordinate-event the Sensor Node immediately sends it to the Sensor Network Master Unit for further analysis and action. The Sensor Network Master Unit evaluates subordinate-event data it receives in the context of its network wide adaptive event profile and Network Master Analytics and decides to either store the data in its data logger or immediately send it to the Communications Hub for further evaluation and potential transmission to the asset owner.

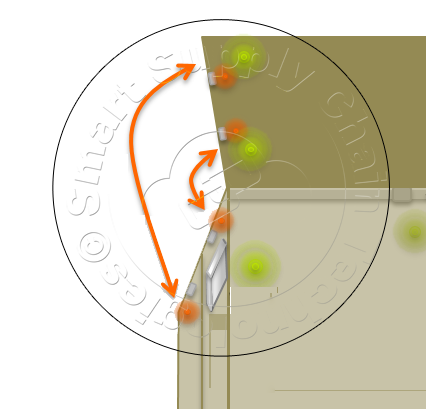

A second security feature uses the same technology that Samsung and LoopPay use for "Near-Field" payment transactions, Magnetic Inductance Communications. S2CT has utilizes this technology and its highly secure near-field characteristics to build a Contactless Door Sensor.  One half of the sensor is deployed on the door and the second half of the sensor is mounted on the superstructure immediately above such that when the door is closed the two halves are separated by between 1/8" and 1/4".

One half of the sensor is deployed on the door and the second half of the sensor is mounted on the superstructure immediately above such that when the door is closed the two halves are separated by between 1/8" and 1/4".  Each half of the sensor produces a small magnetic field around itself. When these two fields are close enough to one another the two magnetic fields intersect and form a continuity. This continuity is observable by the unit mounted on the superstructure and communicates this status to the container's Communications Hub using Sub GHz. When the door is opened and the two sensors separate beyond 1" or so, the magnetic fields separate and the continuity is broken. This is again observed and communicated to the Communication Hub for whatever action it is programmed to take. Three of these Contactless Door Sensors are deployed, one on each container door and one on the Reefer Controller door.

Each half of the sensor produces a small magnetic field around itself. When these two fields are close enough to one another the two magnetic fields intersect and form a continuity. This continuity is observable by the unit mounted on the superstructure and communicates this status to the container's Communications Hub using Sub GHz. When the door is opened and the two sensors separate beyond 1" or so, the magnetic fields separate and the continuity is broken. This is again observed and communicated to the Communication Hub for whatever action it is programmed to take. Three of these Contactless Door Sensors are deployed, one on each container door and one on the Reefer Controller door.

The final container security feature is multiple Door eSeals deployed on the container's door and the Reefer Controller door.  S2CT has developed two low cost versions of its Door eSeal, an industry traditional Cable Loop Seal and a Bolt Seal. Both communicate with the resident Communications Hub using the Sub GHz.

S2CT has developed two low cost versions of its Door eSeal, an industry traditional Cable Loop Seal and a Bolt Seal. Both communicate with the resident Communications Hub using the Sub GHz.  Both of these eSeals use the same Sub GHz subsystem components and software used in the Communications Hub's Sub GHz subsystem, modified slightly to support Near-Field Magnetic Inductance Communication (Mag-I). This unique use of the near-field magnetic inductance technology allows a terminal worker to walk up to a container, randomly grab an eSeal from inventory, either version, touch it to a Communications Hub's Antenna, wait for an LED in the Antenna Module to light, the eSeal is now "associated" with the Communications Hub inside the container, and then install the seal in the target door loops.

Both of these eSeals use the same Sub GHz subsystem components and software used in the Communications Hub's Sub GHz subsystem, modified slightly to support Near-Field Magnetic Inductance Communication (Mag-I). This unique use of the near-field magnetic inductance technology allows a terminal worker to walk up to a container, randomly grab an eSeal from inventory, either version, touch it to a Communications Hub's Antenna, wait for an LED in the Antenna Module to light, the eSeal is now "associated" with the Communications Hub inside the container, and then install the seal in the target door loops.

Another core feature of the Ultra-Secure Smart Reefer Container is the Reefer Controller Interface. The Reefer Controller Interface is a device that plugs directly into the Reefer Controller's I/O port to send command to and retrieve data from the reefer controller.  This could be a Mobile Communications Hub programmed with the appropriate reefer controller communications protocol, a third party Reefer Controller Interface programmed with the appropriate reefer controller communications protocol and wirelessly connected to a Mobile Communications Hub or a third party Reefer Controller Interface with its own Wide-Area-Network and Sub GHz communication capabilities. The Reefer Controller Interface periodically collects data from the Reefer Controller and sends it to a programmed server IP address. The Reefer Controller Interface can also receive reefer commands from an authorized and authenticated remote Network Operations Center and deliver them to the Reefer Controller. S2CT's cloud and embedded software provide a platform for fully managed autonomous reefer operation. The Reefer Controller Interface can independently manage the microclimates within the reefer's cargo area using temperature and humidity data from the Intrusion Network's sensors. With this data the Reefer Controller Interface can precisely manage vents and airflows throughout the cargo area to achieve a uniform cargo area environment. The autonomous Reefer Controller Interface can independently power off a diesel-powered reefer when the outside ambient temperature is persistently cooler than the reefer's temperature set point and restart the diesel when those conditions change. S2CT's Mag-I technology is ideal for communications within a "hazard" area, no RF and spark-arrest provisioned enclosures.

This could be a Mobile Communications Hub programmed with the appropriate reefer controller communications protocol, a third party Reefer Controller Interface programmed with the appropriate reefer controller communications protocol and wirelessly connected to a Mobile Communications Hub or a third party Reefer Controller Interface with its own Wide-Area-Network and Sub GHz communication capabilities. The Reefer Controller Interface periodically collects data from the Reefer Controller and sends it to a programmed server IP address. The Reefer Controller Interface can also receive reefer commands from an authorized and authenticated remote Network Operations Center and deliver them to the Reefer Controller. S2CT's cloud and embedded software provide a platform for fully managed autonomous reefer operation. The Reefer Controller Interface can independently manage the microclimates within the reefer's cargo area using temperature and humidity data from the Intrusion Network's sensors. With this data the Reefer Controller Interface can precisely manage vents and airflows throughout the cargo area to achieve a uniform cargo area environment. The autonomous Reefer Controller Interface can independently power off a diesel-powered reefer when the outside ambient temperature is persistently cooler than the reefer's temperature set point and restart the diesel when those conditions change. S2CT's Mag-I technology is ideal for communications within a "hazard" area, no RF and spark-arrest provisioned enclosures.

S2CT provides the technology and design services to develop a Sub GHz plugin subsystem for any third party Reefer Controller Interface adding the ability to communicate with any S2CT Sub GHz compatible device or any third party proprietary protocol.

The portfolio of core S2CT Hardware Components and Products are designed and produced using the same underlying core components and core software, to the maximum extent possible. This directly benefits S2CT's customers in terms of cost, impacted by the combined S2CT volumes, design testing and ultimately integrity, manufacturing, product support and reliability. Specific products are produced first, by adding or changing value-added application software running on top of the basic application layer and in some cases the embedded Linux Operating System. The second line-of-customization is adding or changing non-core PCB components and the final line-of-customization is the changing to the core PCB components and underlying software layers. All S2CT products are designed to electronically monitor themselves and periodically send "maintenance" data along with their normal payloads to their respective Smart Asset Network in the cloud. All S2CT products are designed to accommodate Over-the-Air software upgrade at the file or module level.

The Universal Enclosure, illustrated here for a Fixed Point Communications Unit Light Pole deployment, is a good example of this underlying maximum utility concept.

The Universal Enclosure, illustrated here for a Fixed Point Communications Unit Light Pole deployment, is a good example of this underlying maximum utility concept.